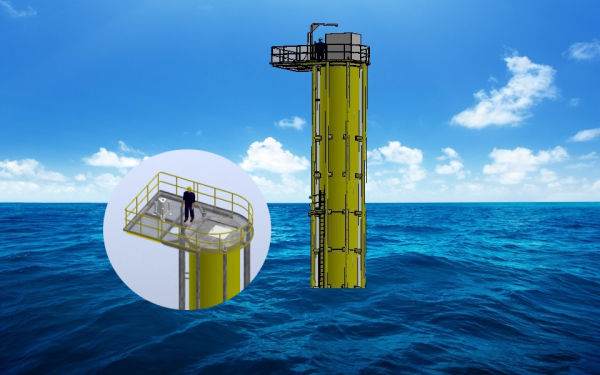

Thirdly, Ocean acknowledged that Sea Met must be easily deployable and recoverable with nothing more than standard offshore tugs in order to offer wind farm developers both the flexibility of very short lead times for deployment and relocation and remove the current cost impediments of doing so.

Utilising current budgets planned for a single mast, wind farm developers could alternatively employ multiple Sea Mets within the development zone. Sea Met also opens up the possibility of multipoint testing to either expand existing developments or to maximise the density and size of future planned sites.

Sea Met can be bespoke designed to operate in any location with water depths up to 60 metres, but to mitigate any unnecessary cost for envisaged operational requirements, two standard models are designed; Sea Met 40 to operate in water depths up to 40 metres and Sea Met 60 to operate in water depths between 40 and 60 metres.

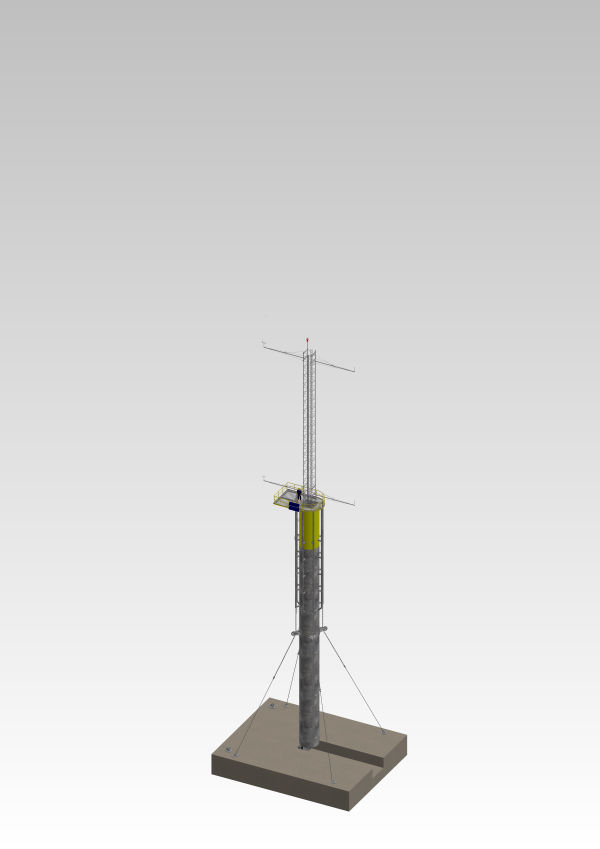

Both Sea Met models utilise the same design concepts and technology of a self-installing free standing Gravity Buoyant Structure (GBS) foundation mated to a tubular hull, which in turn supports a telescopic mast.

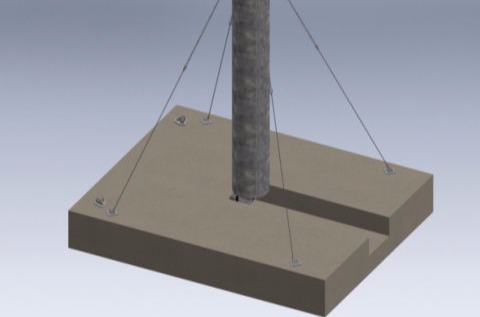

Sea Met uses a concrete and steel cellular Gravity Buoyant System (GBS) foundation.

The gravity base is a rectangular, cellular reinforced concrete structure, comprising several separate ballast compartments.

The foundation is designed to sit on the sea bed and to resist the lateral forces imposed upon it by its tower and tethers.

A steel skirt can be fitted to increase sliding resistance of the base against the sea bed.

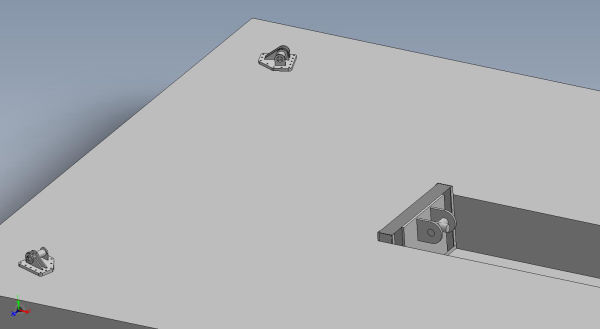

The mast is attached to the centre of the gravity base through an offshore marine quality swivel joint designed to operate over the Sea Met lifetime of 20 years under extreme saltwater corrosive environmental conditions.

The tether cables are anchored to brackets on the foundation structure and are attached to the mast via sheathed fairleads to protect from potential vessel impact.

The main section of each tether comprises multiple 6 x 19 IWRC galvanised and sheathed wire ropes. The exterior of each tether has a silicon based anti-fouling coating to reduce marine growth.

Sea Met is designed to be much simpler and cheaper to commission than traditional offshore masts, with over 80% of the assembly work taking place onshore. For more details, see below.

Sea Met is designed to need very little servicing and maintenance. A photovoltaic array and 600 Watt wind generators are deployed which charge a substantial battery pack, which in turn powers the data collection and transmitting equipment.

All systems on Sea Met can be monitored and interrogated from onshore allowing operators to be forewarned of any defects as soon as they start to occur. This should ensure that potential problems can be rectified prior to any full equipment failure.

In the event that some of the data gathering equipment does fail, Sea Met can be easily boarded from a boat, and the mast climbed. Equipment can either be hauled up for replacement, or if required the mast can be lowered.

In the event of substantial damage to the mast through collision etc, the gravity base will remain intact, and using a standard tug, the foundation can be re-floated and the whole structure towed back to shore for repair and refurbishment.

Sea Met is designed to be much simpler and more economical to install and commission than traditional offshore masts, with over 80% of the assembly work taking place onshore.

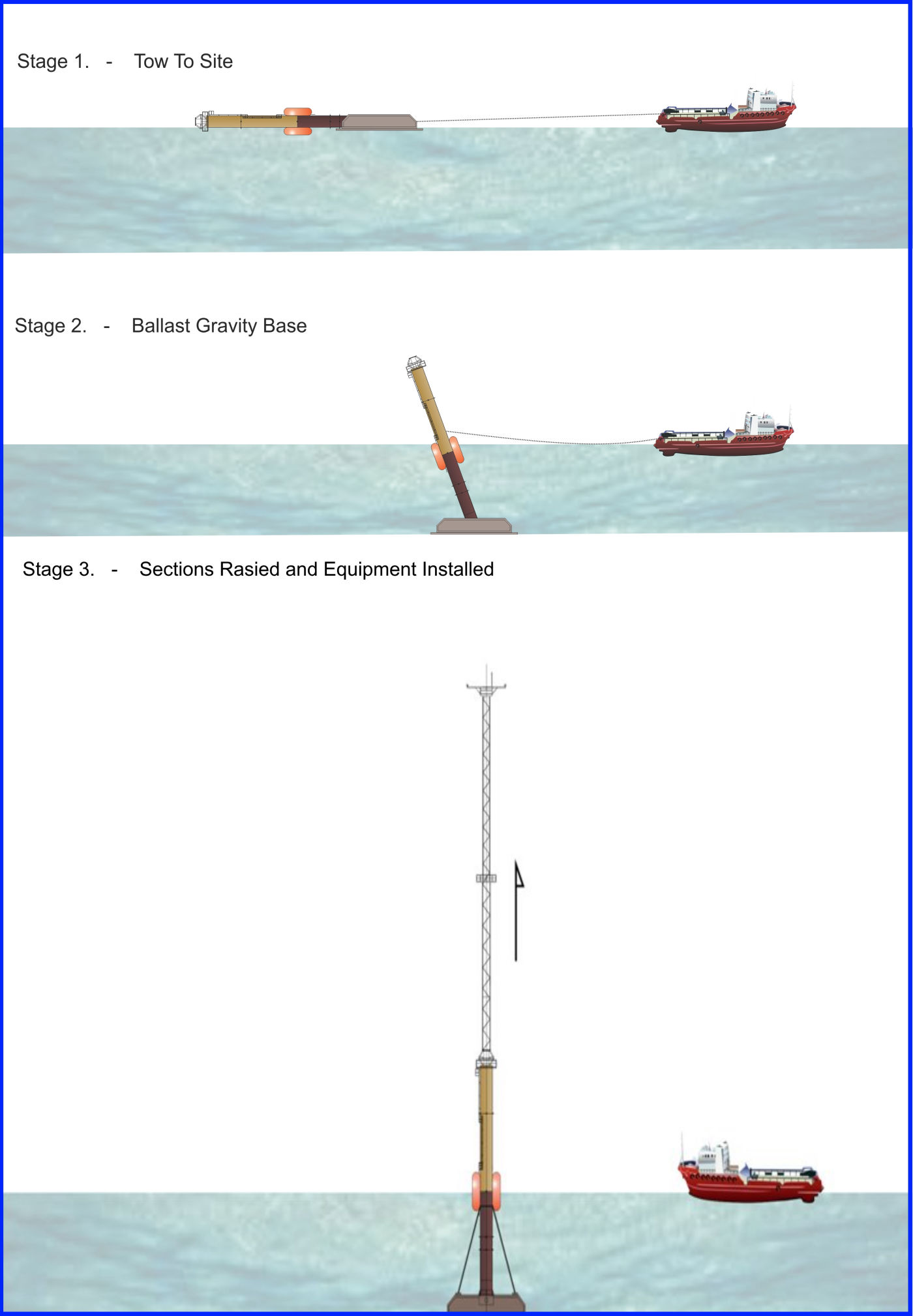

Sea Met is towed out using a conventional offshore tug (STAGE 1). No specialised vessels are required for installation. A standby tug is used to escort Sea Met during the tow in case of emergency manoeuvring. This second tug is also used to expedite positional control and ballasting during installation.

Once on location, the floating Gravity Buoyant Structure (GBS) is boarded and the ballast valves which are connected through hoses to the pumps are opened. The GBS is ballasted to the seabed using seawater ballast actively pumped through the ballast valves. During the ballasted descent to the seabed the position of the Sea Met is controlled by both tugs. The location will be pre-marked and the position will be checked by DGPS.

STAGE 2 : As the GBS descends through the water column, the tower will rotate assisted by buoyancy aids and its own buoyancy until it is almost vertical. Once the GBS is settled on the sea bed in the desired position it is fully ballasted with seawater and the tower is set to the vertical. This is achieved by adjusting the pre-installed the mast tethers together with the use of deck winches on the tug.

Once locked in the vertical position the tower is safe and secure. From now on all assembly work is carried out from the work platform which is accessed via the boat landing. The temporary buoyancy is removed.

The extension of the mast sections is controlled from the work platform. The mast sections are erected using an air or hydraulic winch located on the work platform. Motive power for this is supplied from the designated work boat (probably the second tug).

The mast sections are raised (STAGE 3) using a pre-rigged cable system. The upper section is installed first followed by the next lowest section in order. As each mast section is extended from its stored position, the booms carrying the aeronautical light, anemometers and other instrumentation are attached and the equipment fitted and checked. The wind turbine power (WTG) systems and solar panels are passed over from the designated workboat using a temporary davit jib crane located on the work platform. The system is then commissioned.

Sea Met is designed to be left for long periods monitored remotely without the need for service and maintenance. Inspection is envisaged on a yearly basis.

HEAD OFFICE

Beacon Business Park

Norman Way

Portskewett

Monmouthshire

NP26 5PY

Wales

SOUTH EAST ASIA OFFICE

15th Floor, West Block

Wisma Selangor Dredging

142C, Jalan Ampang

50450 Kuala Lumpur

Malaysia

LINKS

CONTACT DETAILS

Email: info@oceanresource.co.uk

Head Office Phone: +44 (0) 1291 40 80 88

Malaysia Office Phone: +60 13 439 3114

FOLLOW US