Working back from this, it made sense that if Sea Breeze could easily be recovered without damage to the sea bed could also be easily returned to the shore for servicing and maintenance at a fraction of the cost of maintaining any wind turbines fixed offshore.

Thirdly, Ocean acknowledged that Sea Breeze must be easily deployable and recoverable with nothing more than standard offshore tugs in order to offer wind farm developers both the flexibility of very short lead times for deployment and relocation and remove the current cost impediments of using jack up vessels.

Sea Breeze is designed on a simple modular basis, thus allowing all components to be mass produced very economically on assembly lines principals through numerous competitive suppliers anywhere in the country and brought together for final commissioning on any waterside slipways and docks.

Modular design also has the advantages when considering that not all WTG components will reach the end of their serviceable lives simultaneously. Sea Breeze gives wind farm owners the ability to retain and re-use those components with longer service lives, through onshore refits drastically reducing longer term refurbishment costs and also increasing the lifetime viability of every wind farm that utilises Ocean Resource's Sea Breeze design.

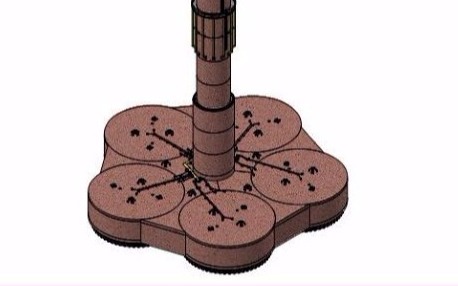

Sea Breeze uses a concrete and steel cellular Gravity Buoyant System (GBS) foundation.

The gravity base is formed by three, five or more circular cellular caissons constructed in reinforced concrete. The caissons are linked through an interconnecting frame arrangement to a central tubular column which stands above the surface and onto which the wind turbine tower is attached through a standard flange arrangement.

The GBS foundation is designed to sit on the sea bed and to resist the lateral forces imposed upon it by its turbine. A steel skirt can be fitted to increase sliding resistance of the base against the sea bed and reduce scour.

Sea Breeze supports any size of wind turbine available or planned.

Sea Breeze is designed to accept any WTG or VAWT of any diameter or height and supporting blade diameters of up to 190m and 12 MW.

The central hub of the foundation structure comprises of a rising column braced by three ballast tanks and is terminated with a standard flange above the planned waterline. This can accept any WTG or VAWT design.

A boat landing platform and ladder to the tower access platform just below the main flange allow access into the tower through a standard door.

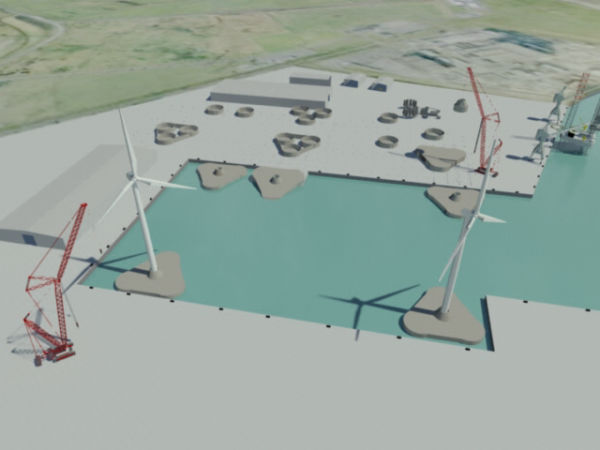

Sea Breeze is constructed using assembly line mass production techniques.

The Foundation structure will be assembled on a simple slipway to a dock into which it will be launched once complete.

This same dock will be used for the delivery by ship of turbine towers, nacelles and blades. A permanent crane will be used for both unloading of components and commissioning.

Once the foundation is floating in the dock, the turbine tower will be lifted and fixed into place, followed by the gearbox and generator nacelle. Finally the blades will be attached and the whole turbine unit can be tested in situ in the dock prior to towing to site and installation.

Once Sea Breeze is commissioned, routine servicing and maintenance will be much the same as other offshore WTG installations.

However Sea Breeze has the huge advantage that at any time it can be easily recovered back to shore for major maintenance, such as gearbox, generator or blade replacement all at a fraction of offshore maintenance costs.

The use of concrete below the surface will give Sea Breeze a much increased life span over steel structures and minimise long term servicing costs.

Sea Breeze is a "Float-out-and-Sink" based design designed to minimise offshore assembly. It is towed out using two basic offshore tugs. The second tug not only provides redundancy for safety purposes, but is also used to expedite the ballasting process during the actual installation.

Ballasting

Once on location, the floating Gravity Buoyant Structure (GBS) is boarded and the ballasting valves connected through hoses to the pumps are opened.

As the GBS fills with pumped water, it begins to sink in a descent that is controlled by both tugs paying out their lines to keep the structure in the correct position.

As the GBS drops below the surface, the tower remains vertical. Once the GBS has been manoeuvred and settled on the sea bed in the desired position it is fully ballasted with sea water.

Once ballasted the tower is safe and can be left. From now on all commissioning work is carried out from the work platform, which is accessed by the boat landing.

The removal and re-deployment process is just as quick and simple but works in reverse.

Installation costs for Sea Breeze are typically 10% of those for fixed piled turbines.

HEAD OFFICE

Beacon Business Park

Norman Way

Portskewett

Monmouthshire

NP26 5PY

Wales

SOUTH EAST ASIA OFFICE

15th Floor, West Block

Wisma Selangor Dredging

142C, Jalan Ampang

50450 Kuala Lumpur

Malaysia

LINKS

CONTACT DETAILS

Email: info@oceanresource.co.uk

Head Office Phone: +44 (0) 1291 40 80 88

Malaysia Office Phone: +60 13 439 3114

FOLLOW US