Thirdly, Ocean Resource acknowledged that Ocean Breeze must be easily deployable and recoverable with nothing more than standard offshore tugs in order to offer wind farm developers both the flexibility of very short lead times for deployment and relocation and remove the current cost impediments of using jack up vessels.

Ocean Breeze is designed on a simple modular basis, thus allowing all components to be mass produced very economically on assembly lines principals through numerous competitive suppliers anywhere in the country and brought together for final commissioning on any waterside slipways and docks.

Modular design also has the advantages when considering that not all WTG components will reach the end of their serviceable lives simultaneously. Ocean Breeze gives wind farm owners the ability to retain and re-use those components with longer service lives, through onshore refits drastically reducing longer term refurbishment costs and also increasing the lifetime viability of every wind farm that utilises Ocean Resource's Ocean Breeze design.

Ocean Breeze uses a concrete and steel cellular Gravity Buoyant System (GBS) foundation.

The gravity base is a rectangular, cellular reinforced concrete structure, comprising several separate ballast compartments.

The foundation is designed to sit on the sea bed and to resist the lateral forces imposed upon it by its buoy, tower and tethers.

A steel skirt can be fitted to increase sliding resistance of the base against the sea bed.

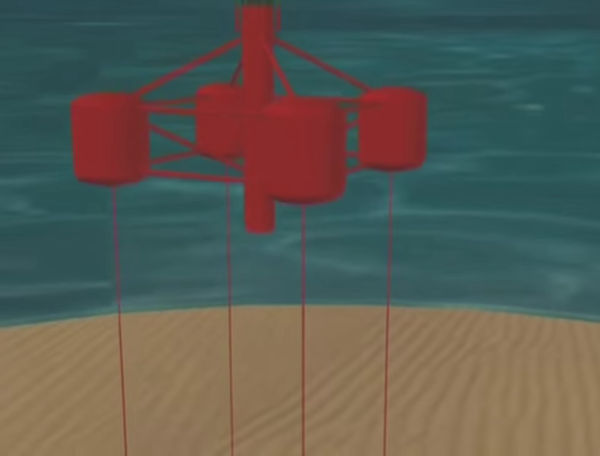

The buoyant hull structure is attached at each corner to the foundation through four tether cable systems that connect to the four hull buoyancy chambers to the gravity base under positive tension.

Each tether is a spiral steel bridge strand wire, galvanized and sheathed in high density polypropylene for corrosion protection. The exterior of each tether has a silicon based antifouling coating to reduce marine growth.

The tether system is designed to eliminate any bending forces upon the buoyant structure and GBS. This is achieved through the use of universal joints with low friction bearing surfaces.

The buoyant or floating hull and turbine support structure consists of four independent steel watertight tanks linked to a central turbine column through a truss system.

The structure is designed to remain below the water under positive tether tension (Tension Leg / TLP structure) with only the turbine column protruding above the surface, thus minimising the impact of breaking waves.

The turbine support column is also watertight and terminates above the waterline with a flange to match the desired column. Landing platform and access decks are provided to allow boarding from a boat.

Ocean Breeze is designed to be much simpler and cheaper to commission than traditional offshore turbines, with all the commissioning work taking place onshore.

Two Stage Installation.

(1) The Gravity base is launched and towed out using two basic offshore tugs. Once on location, the floating Gravity Buoyant Structure (GBS) is boarded and the ballasting valves which are connected through hoses to the pumps are opened. As the GBS fills with pumped sea water it begins to sink. Both tugs pay out their lines to control the decent and to ensure the structure is correctly positioned on the sea bed. The tether cables are held on the surface attached to a locator buoy.

(2) The buoyant hull is launched and moored in dock whilst the wind turbine is installed and fully commissioned. It is then towed offshore and into position and the tethers are retrieved. A seperate cable is used to draw the buoyant structure under the surface so the tethers can be connected in an operation lasting only a few hours.

Ocean Breeze is then safe and can be left. From now on all assembly work is carried out from the work platform, which is accessed by the boat landing. The tower's power transmission cable is then plugged in to the SeaNode hub. You may want to watch the installation sequence video

This rapid deployment process using standard tugs needs only needs two short weather windows for completion, considerably raising efficiency and slashing installation costs by some 90%.

The removal and re-deployment process is just as quick and simple but works in reverse.

Ocean Breeze is designed to need very little servicing and maintenance. The buoyant hull is positioned well below the surface to reduce wave induced fatigue damage.

In extreme weather, the system incurs lateral movement of less than 10 metres from centre, with a maximum pitch and roll of less than 1.35 degrees. Maximum acceleration levels never exceed 0.35G

All systems on Ocean Breeze can be monitored and interrogated from onshore allowing operators to be forewarned of any defects as soon as they start to occur ensuring that potential problems can be rectified prior to any full equipment failure.

For routine service and maintenance, the turbine can be easily boarded from a boat.

For major re-fits the turbine can be disconnected from the gravity base and towed back to port.

In the event of substantial damage to the turbine through collision etc, the gravity base will remain intact, and the buoyant structure will continue to float even with substantial damage to two of its chambers. Floating; the whole structure can be recovered back to shore using only standard tugs for repair and refurbishment.

HEAD OFFICE

Beacon Business Park

Norman Way

Portskewett

Monmouthshire

NP26 5PY

Wales

SOUTH EAST ASIA OFFICE

15th Floor, West Block

Wisma Selangor Dredging

142C, Jalan Ampang

50450 Kuala Lumpur

Malaysia

LINKS

CONTACT DETAILS

Email: info@oceanresource.co.uk

Head Office Phone: +44 (0) 1291 40 80 88

Malaysia Office Phone: +60 13 439 3114

FOLLOW US